We have many years of experience supplying our heat exchangers for dairy applications.

Plate Heat Exchangers (PHE) are the most cost-effective way to cool milk. Milk is cooled at source to reduce the growth of bacteria.

PHEs are very efficient, not only can you achieve very close temperatures, but you also do not need much water to cool the milk. You can use water to cool the milk down initially and use a refrigerated milk tank or use a PHE for both stages.

We have a range of Gasketed Plate Heat Exchangers that have been specifically designed to efficiently cool milk using mains water and iced water. We offer two types as standard:

Single Section - Milk is cooled using mains water.

Two Section - Milk is cooled using both mains water and iced water in a more compact design.

Heat exchangers can be supplied to our standard design specifications or selected to your specific requirements.

Stainless Steel frames are available which are more hygienic and allow for the unit to be washed down regularly without rust forming.

Multiple hygienic connections types are available such as tri-clamp and RJT.

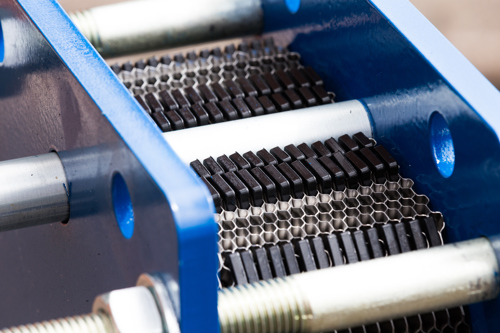

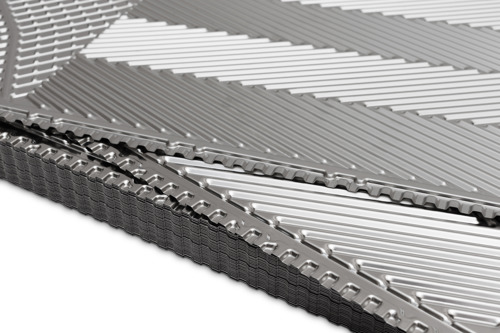

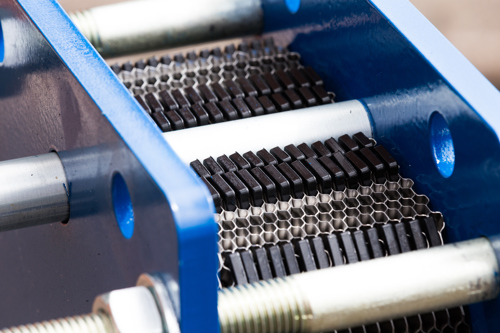

Our extensive range of Gasketed Plate Heat Exchangers provide compact thermally efficient solutions to your heat transfer requirements. The main advantage of a gasketed plate heat exchanger is that it is possible to open up the inside components for cleaning and maintenance purposes. It also allows extra plates to be added should your process conditions change

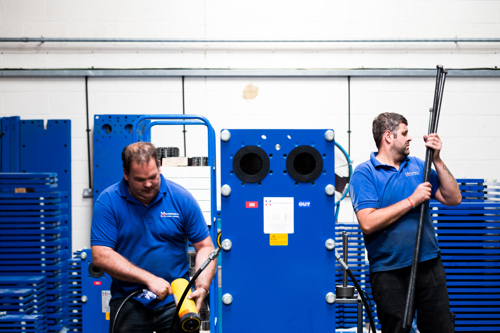

The Gasketed Plate Heat Exchangers are manufactured in our UK factory from stock components, which means that we can normally deliver fully assembled and tested units extremely quickly.

Plate Heat Exchangers transfer heat energy from one side to another without the two products on either side mixing. So you can install them between the boiler and process circuit for example to separate the two circuits. Plate heat exchangers are a very popular choice mainly due to the compact size and high efficiency design that they offer.

Our stock range of Brazed Plate Heat Exchangers are WRAS approved subject to a maximum operating temp of 100°c

Our superb facilities and manufacturing set us apart

Get in Touch Today

Get in Touch Today

Get in Touch Today

Get in Touch Today

Get in Touch Today