Our Range of Plate Heat Exchangers (PHE) are a very cost-effective way to cool your wort. Reducing the wort to pitching temperature quickly is very important to beer quality, and PHEs both cool the wort and preheat the brewing water.

PHEs allow you to efficiently recycle the energy initially used in the boiling of the wort to heat up cool water to be used elsewhere in the brewing process. Meaning PHEs can save a lot of money in the beer making process.

Using a PHE for wort cooling allows you to quickly chill your wort, which reduces the risk of the wort becoming infected by microorganisms, reduces the formation of Dimethyl Sulphide (DMS) and an increase in cold break.

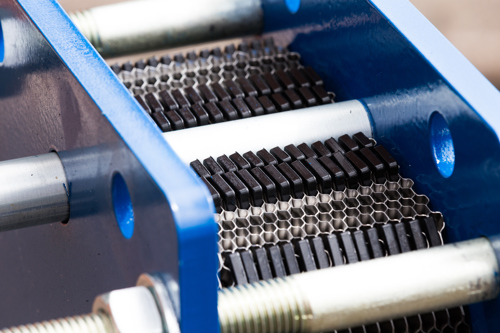

The PHE separates the fluids by creating a barrier between the wort and the cooling water which allows the transfer of heat only. No crossover of fluids. Our design is ultra-efficient and has extra surface area to allow a longer time between cleans.

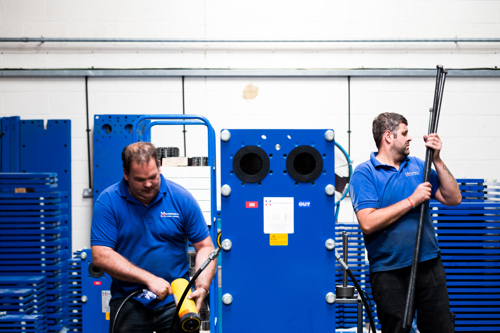

We have designed and built heat exchangers for wort cooling applications for years. Stainless Steel frames are available which are more hygienic and allow for the unit to be washed down regularly without rust forming. Multiple hygienic connections types are available such as tri-clamp and RJT.

We have Gasketed Plate Heat Exchangers that can be designed to efficiently cool your wort. The advantages of these:

Heat exchangers can be supplied to our standard design specifications or selected to your specific requirements.

Our extensive range of Gasketed Plate Heat Exchangers provide compact thermally efficient solutions to your heat transfer requirements. The main advantage of a gasketed plate heat exchanger is that it is possible to open up the inside components for cleaning and maintenance purposes. It also allows extra plates to be added should your process conditions change

The Gasketed Plate Heat Exchangers are manufactured in our UK factory from stock components, which means that we can normally deliver fully assembled and tested units extremely quickly.

Plate Heat Exchangers transfer heat energy from one side to another without the two products on either side mixing. So you can install them between the boiler and process circuit for example to separate the two circuits. Plate heat exchangers are a very popular choice mainly due to the compact size and high efficiency design that they offer.

Our stock range of Brazed Plate Heat Exchangers are WRAS approved subject to a maximum operating temp of 100°c

Our superb facilities and manufacturing set us apart

Get in Touch Today

We have a range of Gaskets in stock that are WRAS approved (subject to a maximum operating temp of 100°c) suitable for DHW applications.

Get in Touch Today