UK Exchangers supply a range of heat exchanger and fan packages which heat medium pressure air, suitable for drying grain and many other products.

Why dry grain?

Although certain crops can be produced throughout the year, the major food crops such as cereal grains and tubers, including potatoes, are seasonal crops. Consequently, the food produced in one harvest period must be stored for gradual consumption until the next harvest, and seed must be held for the next season’s crop. The same can be said of woodchip which is used as a fuel during winter when the wood has not been seasoned. Active drying allows these commodities to be useful all year round.

As part of safe crop storage, the harvest is often washed and cleaned. One of the most critical factors in successful grain storage is the moisture content of the crop. High moisture content leads to storage problems because it encourages fungal and insect problems.

An additional consideration is weight and usability. Woodchip is a better-quality fuel when it is dried as the moisture content must be evaporated during combustion. Roughly speaking you lose 1% of energy for every 1% of Moisture content during combustion. Another factor is weight and transport costs, fuels with higher moisture contents are also more costly to transport for a given volume.

How long does it take to dry?

Grain drying time depends on the size and efficiency of the dryer, the moisture content of the grain and the volume or weight of grain to be dried. The most important factor is the product store, and you should consult your provider about drying specifications.

Drying Floors:

The product is stored on top of a fully perforated floors and air blown up through the product. Moisture moves from the product into the air and is then expelled to atmosphere. Usually used on large scale dryers.

Drying Containers:

Similar to drying floors, the product is stored inside a large container and air blown through the product. However, the waste heat is more easily captured for heat recovery and is usually a smaller scale operation.

Drying Kilns:

Usually seen with Log drying applications but also for drums and bricks, these use a much smaller fan to heat up the air surrounding the product and maintaining the temperature. This draws the moisture from the centre of thicker products. Usually built into modified sheds or containers

Back pressure for grain is usually 750 - 1000 Pa, however woodchip is more porous and so the pressure will be lower; in the region of 250–600 Pa depending on floor depth and chip grade.

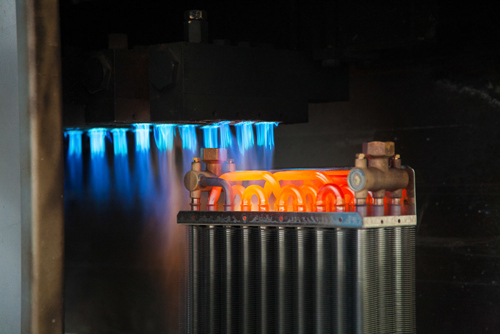

We can supply Finned Tube Coils for new installations or as made to measure replacements for existing damaged coils.

We manufacture Finned Tube Coils to order, therefore we can achieve the right design, materials and construction for most applications.

Our extensive range of Finned Tube Coils are designed for HVAC, and Industrial Process applications.

UK Exchangers Ltd can produce fully welded, stainless steel finned tube coils. Suitable for the food processing industry and/or steam applications.

Finned tube coils transfer heat energy from a steam or liquid (inside the tubes) into air (across the fins) or vice versa.

We produce finned tube coils from one off small applications to much larger commercial and industrial projects. The list of applications are endless!

Get in Touch Today

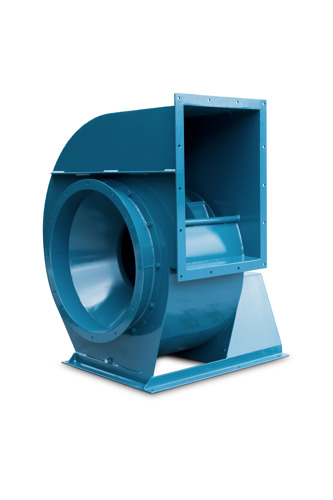

Our range of Industrial Dryers have been designed to heat air using hot water for applications such as drying Grain, Woodchip, Logs, Paper, Bricks and many more using a heating medium such as hot water from a boiler, engine or heat pump.

The outputs of the standard range are from 100 kW to 1500 kW with air delivery pressures up to 1000 Pa.

Each Industrial Dryer is delivered fully assembled for easy on-site installation or if preferred, in component form.

Our standard range is based on the following:

Hot Water: 80°C flow / 60°C return

Air: 15°C inlet / 55°C outlet

For alternative air and/or water temperatures or air pressures please contact our sales department.

We can also supply heat exchangers that use thermal oil, steam or high pressure hot water as the heating medium.

Get in Touch Today

Get in Touch Today