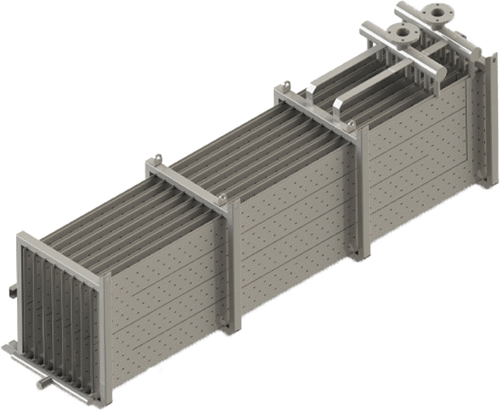

Pillow Plate Heat Exchangers can be made to order in numerous configurations and sizes. These are suitable for many different applications such as in tank heating and cooling, water source heat pumps (in rivers and lakes), falling film heat exchangers, food process heating and industrial liquid to air applications.

The pillow plate is formed by laser spot welding two sheets of steel together at the edges and in strategic positions across the face of the plate. Connections are then welded on and the plates are inflated using compressed air or water at pressures up to 300 bar.

Get in Touch Today